河北北方光科智能装备有限公司

咨询热线

13601388625

联系电话:13601388625

地址:河北省廊坊市三河市李旗庄镇李木耳村南102国道旁鑫鑫科达有限公司院内

作者:admin1 发布时间:23-12-11 04:14

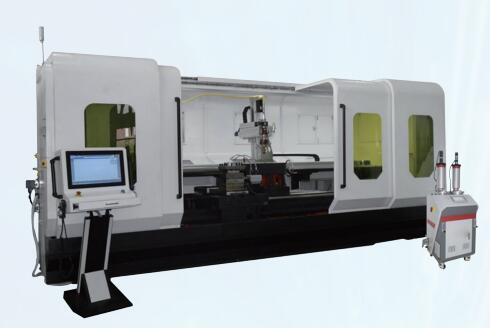

激光熔覆是一种具有高新科技的表面改

性与装备维修技术,能够显著改善金属表面的耐磨、耐蚀、耐热、抗氧化等性能。具有熔覆层与基体呈冶金结合且稀释率低、基体变形小、工艺易于实现自动化等特点。该技术主要应用于液压支架立柱、中缸、大型设备主轴等零件的耐磨耐蚀修复及表面强化处理。

Laser cladding is a kind of surface modification and equipment maintenance technology with

high and new technology, which can significantly improve the wear resistance, corrosion resistance,

heat resistance and oxidation resistance of metal surface. It is featured by metallurgical combination between cladding layer and matrix, low dilution rate, small matrix deformation and easy automation of process. The technology is mainly applied to the wear-resistant and anti-corrosion repair and surface strengthening treatment of hydraulic support column, middle cylinder, main shaft of large equipment and other parts.

性能优势:

1.输出功率大,电光转换效率高(大于40%),熔覆效率高。

2.矩形光斑,尺寸可调,单道熔覆宽度大,能量集中度好、利用率高。对工件热影响小,变形小。

3.激光器集成度高,体积小,易损件少,自动化程度高,易于操作和维护。

Performance advantages:

1.High output power, high electro-optical conversion efficiency (more than 40%) and high

cladding efficiency.

2.Rectangular spot, adjustable size, large single cladding width, good energy concentration and

high utilization rate. Small thermal impact and deformation on workpiece.

3.High laser integration, small size, less vulnerable parts, high degree of automation, easy operation and maintenance.